Production scheduling is one of those things that seems simple, but they are not. For many small manufacturers, keeping track of what needs to be built, when, and in what order quickly turns into a daily fire drill. Between urgent orders, material delays, machine downtime, and changing priorities from customers or sales, the plan you made in the morning often doesn’t survive until lunch. That chaos isn't because the team lacks skill or effort; it's because the tools and processes in place aren’t designed to handle the reality of the shop floor.

One of the first issues we see is the lack of visibility. It's common for companies to not really know how much work is sitting in production at any given moment. Work orders are often spread across papers, spreadsheets, emails, or an ERP system that’s more focused on data structure than real-world usability. Without a clear picture of what’s in the queue, what’s delayed, and what’s coming next, managers and supervisors end up reacting instead of planning.

It's not uncommon to find environments where the scheduling tool shows nothing but an internal process key — a code that references the product, the operation, and the order. From a data standpoint, that makes sense. But from a human perspective, it means almost nothing. The people on the floor don’t speak in database keys; they speak in parts, jobs, and due dates. If the system isn't built for the user, it becomes a bottleneck instead of a guide.

On the other side, there are systems with scheduling tools that try to control every second of production. That level of precision might sound good in theory, but it rarely holds up in practice. A machine breaks, a supplier is late, or an operator calls in sick — and the whole plan collapses. Then, someone prints a new schedule, production ignores it, and it’s back to square one. Over time, some companies go the other direction and just stop scheduling altogether.

Scheduling is hard for a reason. It’s the part of production that ties everything together: material availability, process sequencing, machine capacity, staffing, and delivery deadlines. Systems like MRP and MRP II exist to manage that complexity, but they require structure and discipline to work. When the underlying processes are messy or half-used, those systems end up underperforming, or worse, being ignored entirely.

Some companies use an ERP just to generate a list of operations, then hand those off to supervisors to figure out. What usually follows is a turf war between departments. Supervisors prioritize their jobs based on whatever is most urgent, or whoever is shouting the loudest, and the production manager ends up running from machine to machine, asking what’s going on. It’s not that anyone’s doing something wrong; it’s that the system in place isn’t helping them do it right.

The answer isn’t just more software; it’s better alignment between tools and real-world workflows. A good scheduling system doesn’t need to be fancy, but it does need to be built with the people using it in mind. It should help prioritize, track progress, and adapt to change without overwhelming the user. That means surfacing the right information — what the job is, when it’s due, what steps it needs to go through — not hiding behind complex codes or outdated interfaces.

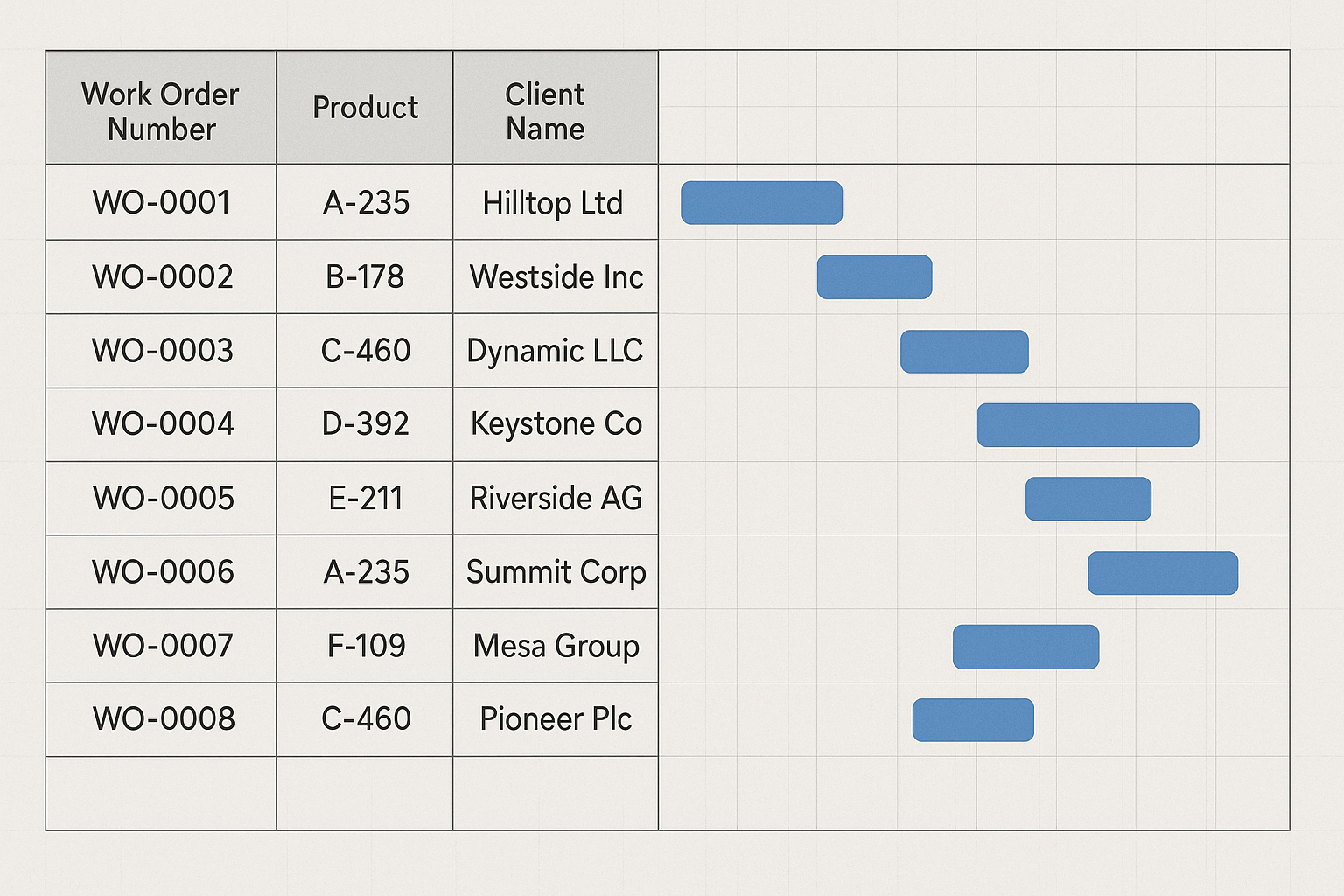

At Nengatu, we’re building our scheduling tools to help the user become more effective. Our approach is simple: each work order has a priority, and each product inside it can have its own. From there, the system calculates dependencies and organizes the workflow accordingly. Most importantly, it’s visual. Because when you can see what’s happening, it’s much easier to make good decisions.

Of course, even the best tool won’t fix a broken process. But when the processes are in place and the right tool is available, the chaos starts to fade. Scheduling becomes less of a daily emergency and more of a coordinated effort. And in manufacturing, that can make all the difference.